Rotary Unions

What is a Rotary Union?

The rotary union is also known as a rotating joint, rotary couplings, rotary swivels, or even fluid rotary union, besides a couple of other names which can be confusing.

A rotary union is a joint that actually acts as a seal between a stationary part and a rotating part of the device or a machine.But besides that, the rotary union also helps supply the flow of fluid inside or outside a rotating part on a device.

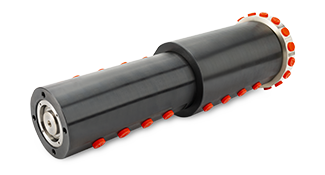

Rotary union is a very small device that looks simple on the outside and yet the way it’s built on the inside matters as it connects stationary with a rotational part in a machine (or a device).Therefore, the rotary union can be considered a 2-in-1 device that acts as a joint in a machine.

Rotary Unions by Media

Learn More About Rotary Unions

What is a Rotary Union Used for?

Rotary union comes in various shapes, sizes, and types so it fits various purposes, needs, and industries.

It is widely used as a device to connect rotating equipment to fixed piping in appliances where transfer of steam, oil, coolant, water, or air is needed.

Therefore, rotary joints are used in aerospace, robotics, food and beverage, oil and gas, medical devices, and many other devices such as hydraulic excavator, wind turbine, hose reel (offshore),cnc machine, robot, lifting device, winch.

How Does a Rotary Union Work?

First and foremost, rotary union provides a seal between a stationary and rotational part of a device, and there are four main seal types it can provide:

Pressure joint seal

Plastometric seal

Hydrostatic seal

Mechanical seal

Upon the connection between two parts, rotary union allows a connection (moving) which also allows a flow of fluid.

The connection is preserved and undisturbed flow of media is available, even during the moving action.

Which is the Inlet of a Rotary Union?

The inlet of a rotary union is at the top where the inlet for the fluid is attached and securely connected to the rotary union.

However, just below the inlet of a rotary union is the drainage outlet which should also be connected.After both inlet and outlet are connected, rotary union can be connected to a machine.

There are also many other details to pay attention to when installing the rotary union to a machine, such as the position, thread advice, hose directions, and others. This is well described and explained in the following video.

How to Connect a Rotary Union to a Shaft?

Rotary union can be installed in 3 easy steps, no matter the type of a rotary union.

The rotary union is installed to a shaft (stationary part) of a device with the help of threads. Keep in mind that rotary union should be connected to a shaft only after the inlet and outlet hoses are connected.

All mounting surfaces need to be clean as dents or chips can cause damage. Thread direction of a rotary union should always match the shaft’s thread direction (never vice-versa).

And lastly, the rotor should be tightened to the torque advised by the rotary union manufacturer.

What are the Types of Rotary Union Seals?

The heart of a rotary joint is the seal. Seals prevent the media from leaking outside the rotary joint during operation. Seal types can be divided into pushrod face mechanical seals, non-pushrod face mechanical seals, lip seals, plastomeric seals, hydrostatic seals and O-ring seals.

How to Unseal a Rotary Union?

Rotary unions can be unsealed from a stationary part of a device with a proper tool to unseal the thread.

However, the inside of rotary unions can also be unsealed for the purpose of repairs, and this is something that requires a lot more knowledge and it isn’t always recommended since rotary unions have a lifespan and sometimes they’re better to be replaced.

Rotary Union Types

Rotary unions come in various shapes, sizes, and types. Even though they are made to fit different industries, devices, and machines, they can also be designed to fit custom needs.

Even though there are many types, rotary union types can be categorized to the following uses:

One channel rotary unions

Low-speed rotary unions (single channel)

Dual passage rotary unions

No matter the type, each rotary union is made of the same components with differences in design. The main components of a rotary union include a shaft, bearings, seals, housing, and a retaining ring.

Each rotary union type will determine the rotating speed, pressure, and temperature.

There are also various rotary union types that specifically help transfer thermal oil, water, steam, hydraulic oil, air, or coolant. On top of that, you can get custom rotary unions built for specific purposes, and there are also versatile rotary unions that fit different fluids and gasses.

©2022 Orbinexus . All rights reserved Site Map

Pay Online

Pay Online Get A

Quote

Get A

Quote Deutsch

Deutsch